Direct To Film (DTF) Printing transforms bulk order handling by directly printing graphics onto fabrics and paper, eliminating transfer papers. Ideal for custom apparel, signage, and promotional materials, DTF ensures precise specifications and quality consistency. Efficient pre-production planning involves calibrating printers, preparing digital files, sourcing materials, and organizing storage. Post-production management includes thorough quality control checks, organized receiving, proper film storage, and test prints to guarantee pristine results. Regular calibration and staff training maintain consistent quality standards in bulk DTF printing.

In today’s visual landscape, bulk film printing remains a cornerstone of many industries. For businesses leveraging direct to film printing, efficient workflow management is paramount. This article explores the art of handling bulk orders through direct to film printing, delving into key strategies at every stage—from pre-production and preparation to post-production and quality control. Discover how these tactics optimize your process, ensure top-tier results, and drive customer satisfaction.

- Understanding Direct to Film Printing for Bulk Orders

- Pre-Production and Preparation Strategies

- Post-Production Management and Quality Control

Understanding Direct to Film Printing for Bulk Orders

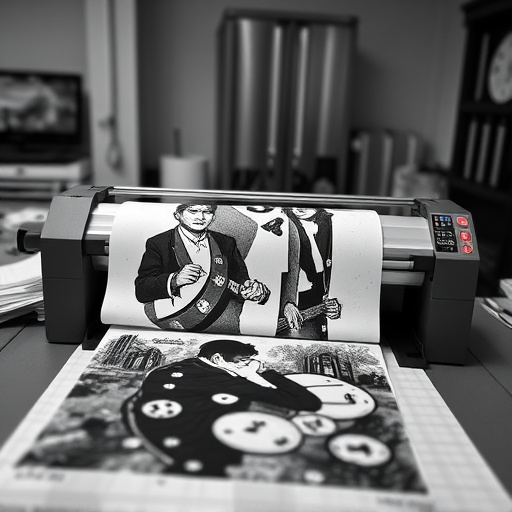

Direct to Film (DTF) Printing is a game-changer when it comes to handling bulk orders in the film printing workflow. This technology allows for precise, high-quality application of graphics directly onto various materials, such as fabrics or paper, without the need for intermediate transfer papers. For businesses dealing with custom graphic tees or personalized hoodies, DTF offers an efficient and cost-effective solution.

By eliminating the extra steps involved in traditional printing methods, DTF streamlines the production process. It’s particularly beneficial for bulk orders as it ensures consistency in quality and reduces the risk of errors during the printing stage. This method is ideal for creating custom designs on a large scale, whether for apparel, signage, or promotional materials, ensuring that each piece meets the desired specifications.

Pre-Production and Preparation Strategies

During pre-production, establishing a robust strategy is key when handling bulk orders for film printing. This involves careful planning and consideration to ensure smooth workflow. First, assess the order details, focusing on quantity, fabric types, and print specifications. For instance, Direct To Film (DTF) printing offers an efficient method suitable for dark fabrics, allowing for vibrant logos on clothing brands. Prepare digital art files according to the specific DTF printing requirements, ensuring they meet the necessary resolution and format standards.

Additionally, source high-quality printing materials and set up the print environment accordingly. This may include calibrating printers, ordering custom ink sets if needed, and organizing storage for raw materials. Efficient preparation in this phase significantly contributes to timely execution of bulk orders, ensuring satisfaction for clothing brand clients seeking logos dtf for their products.

Post-Production Management and Quality Control

Effective post-production management is pivotal when handling bulk orders for direct to film printing (DTF). This involves meticulous quality control checks at every stage to ensure pristine prints. Start by organizing an efficient receiving process, where incoming orders are verified against specifications, and any discrepancies promptly addressed. Implement a robust system for storing and managing print films, ensuring they’re labeled, dated, and stored under optimal conditions to maintain their integrity.

For T-shirt printing or other apparel applications using DTF transfers, quality control should include rigorous testing of color accuracy, resolution, and overall image fidelity on test prints before full production runs. Regular calibration of direct to film printers and ongoing staff training in quality assurance procedures are also essential. This ensures consistent results across all orders, maintaining customer satisfaction and the high-quality standards that bulk DTF printing demands.

Direct to film printing is a game-changer for handling bulk orders in the film industry, offering efficient production and cost-effective solutions. By implementing strategic pre-production preparation and rigorous post-production quality control, printers can ensure exceptional results. This streamlined workflow not only enhances productivity but also guarantees that each bulk order meets the highest standards, making it a reliable choice for film producers and studios alike.