Direct to Film (DTF) Printing revolutionizes print-on-demand services by eliminating traditional printing methods, allowing businesses to swiftly produce high-quality custom products with intricate designs. Ideal for apparel, DTF enables designers to bring unique personalized ideas to life on various materials, particularly light fabrics, leveraging vibrant color outcomes and precise details. By adopting strategic planning, best practices, and top-tier technology, POD stores can enhance product quality, satisfy customers, and maintain a competitive edge in the market.

Direct to film printing is transforming the print-on-demand industry, offering a cutting-edge solution for stores seeking efficient, high-quality production. This technology eliminates traditional plate-making processes, enabling rapid, precise printing directly onto various materials. In this article, we explore the fundamentals of direct to film printing, its advantages for demand-driven stores, and essential implementation strategies for successful integration into your workflow.

- Understanding Direct to Film Printing Technology

- Benefits of Direct to Film Printing for Print-On-Demand Stores

- Implementation and Best Practices for Successful Integration

Understanding Direct to Film Printing Technology

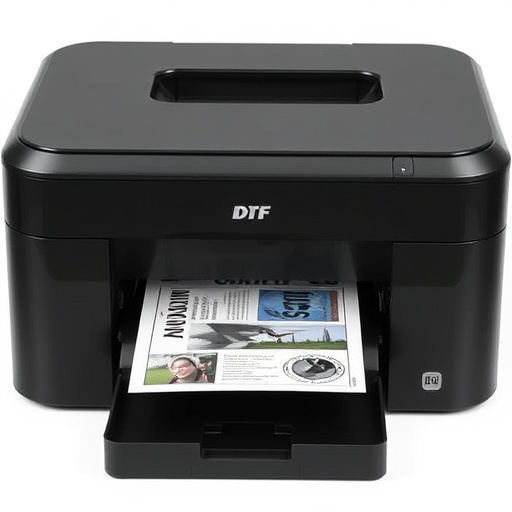

Direct to Film (DTF) Printing is a cutting-edge technology that has revolutionized print-on-demand services. This innovative process eliminates the need for traditional printing methods, such as plate preparation and offset printing, by applying ink directly onto film or vinyl. DTF printing offers a fast and versatile solution for creating custom designs on various materials, particularly in the apparel industry.

The technology involves using specialized printers that deposit ink onto a flexible substrate, typically a thin film or vinyl sheet. After the ink is applied, a clear top coat is added to protect the design. Once the ink dries, it forms a durable, high-quality print ready for application onto fabric or other desired surfaces. DTF for apparel allows businesses and designers to effortlessly bring unique, personalized designs to life, catering to the growing demand for custom clothing and accessories in today’s market. With its precision and efficiency, cold peel DTF transfers ensure excellent results, making it a popular choice for print-on-demand stores aiming to offer timely and high-quality products.

Benefits of Direct to Film Printing for Print-On-Demand Stores

Direct to Film (DTF) Printing offers Print-On-Demand (POD) stores a host of advantages that set it apart from traditional printing methods. One of its key benefits is speed and efficiency; DTF printers can produce high-quality prints on demand, allowing businesses to meet rapid market changes and customer preferences. This method is particularly suitable for POD stores catering to diverse niches, as it enables them to offer a wide range of custom products with intricate designs without incurring significant setup costs or lengthy production times.

Additionally, DTF Printing provides excellent versatility when it comes to printing on various materials, especially dark fabrics. Unlike some printing techniques that struggle with deep colors and dark surfaces, DTF printers achieve vibrant, accurate results on a spectrum of fabrics, expanding the design possibilities for POD stores. With access to top-tier DTF printers, such as the best dtf printer models available, these businesses can stay ahead in the market by offering cutting-edge printing solutions that enhance product quality and customer satisfaction.

Implementation and Best Practices for Successful Integration

Implementing Direct to Film (DTF) Printing for Custom Graphic Tees involves careful planning and best practices to ensure a seamless integration with your print-on-demand store. The first step is selecting a high-quality DTF printer compatible with your production volume and target materials, such as light fabrics. This technology allows for precise, vibrant printing directly onto film, which then serves as a transfer medium for textiles, eliminating the need for traditional screens or plates.

Best practices include optimizing print profiles to achieve crisp details and vibrant colors on various fabrics, especially when using heat press techniques. Regular maintenance of your DTF printer is crucial, including keeping nozzles clean and ensuring proper film alignment. Additionally, managing inventory efficiently, pre-testing designs on different materials, and offering a range of customization options will enhance customer satisfaction. For instance, dtf printing for light fabrics requires specific settings to prevent smudging or fading while maintaining image quality.

Direct to film printing has emerged as a game-changer in the print-on-demand industry, offering efficient production and exceptional quality. By understanding this technology’s capabilities and implementing best practices, stores can streamline their operations and cater to diverse customer demands. The benefits of direct to film printing are clear, from faster turnaround times to cost-effectiveness for small batch orders. As print-on-demand businesses seek to stay competitive and meet the ever-evolving needs of their clients, embracing this innovative technology could be the key to unlocking new opportunities and achieving success in today’s dynamic market.